Plazma 4 osie na LinuxCNC

-

kamar

- Lider FORUM (min. 2000)

- Posty w temacie: 39

- Posty: 16251

- Rejestracja: 18 wrz 2010, 06:17

- Lokalizacja: Kozienice

- Kontakt:

Re: Plazma 4 osie na LinuxCNC

To co mam na maszynie to wysyłam. Czy działa i jak działa nie wiem , dawno nie odpalane.

- Załączniki

-

- plazma.zip

- (13.04 KiB) Pobrany 101 razy

-

- plasma-thc.zip

- (117.93 KiB) Pobrany 134 razy

-

senio

Autor tematu - ELITA FORUM (min. 1000)

- Posty w temacie: 42

- Posty: 1459

- Rejestracja: 25 maja 2006, 14:39

- Lokalizacja: koło.wlkp

Re: Plazma 4 osie na LinuxCNC

Dzięki. Baza jest to się coś wyrzeźbi. Teraz nie mam czasu ale później na to wszystko spokojnie popatrzę.

Dodane 1 godzina 58 minuty 46 sekundy:

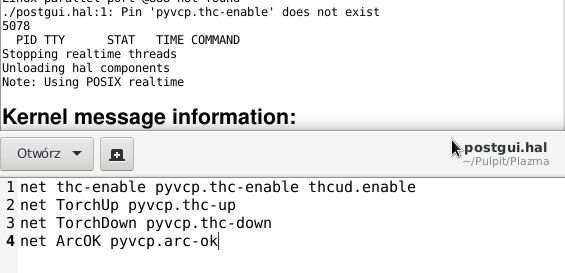

Znalazłem ten postgui.hal do światełek i załączania. Zamontowałem go w halu, ale tu bez pomocy to się nie obędzie. Ja nie wiem co z tym zrobić i dlaczego tak jest oraz gdzie co dodać zmienić. Generalnie mam konfig zrobiony. Wszystko wg. mnie działa. Tylko ten panel dopisać żeby działał pozostało.

Trochę tą całą dyskusję przemyślałem i Kamar ma rzeczywiście rację. Do cięcia profili nie ma sensu THC używać. Postprocesor wykorzystam gościa z forum linuxa i tyle. Nawet nie musiał bym tego panela wtedy montować. Ale też trochę ustaleń jest, że jednak kawałek stołu do palenia drobiazgów też będzie. Nie za duży ale będzie. A wtedy w opcji THC się przyda, więc dobrze by to uruchomić i niech będzie. Jak ktoś coś podpowie jak to zamontować to będzie miło.

Dodane 42 minuty 51 sekundy:

Dobra, poradziłem sobie jednak z tym panelem

-

cyna's

- Specjalista poziom 1 (min. 100)

- Posty w temacie: 6

- Posty: 159

- Rejestracja: 11 mar 2012, 12:26

- Lokalizacja: Łódzkie/Wielkopolskie

Re: Plazma 4 osie na LinuxCNC

wklejaj całe komunikaty i pliki bedzie łatwiej szukać problemów.

Pokaż plik z lampkami i przyciskiem bo tam też może być coś nie tak. ( ten .xml )

To dobrze ze się udało

Pokaż plik z lampkami i przyciskiem bo tam też może być coś nie tak. ( ten .xml )

To dobrze ze się udało

Retrofit Fadal VMC 15 - LinuxCNC

fadal-vmc-15-linux-cnc-t99497.html

Retrofit Elektrodrążarka drutowa SCX-2 / WBKX-6 ---> LinuxCNC

elektrodrazarka-drutowa-scx-2-wbkx-6-t98504.html

fadal-vmc-15-linux-cnc-t99497.html

Retrofit Elektrodrążarka drutowa SCX-2 / WBKX-6 ---> LinuxCNC

elektrodrazarka-drutowa-scx-2-wbkx-6-t98504.html

-

senio

Autor tematu - ELITA FORUM (min. 1000)

- Posty w temacie: 42

- Posty: 1459

- Rejestracja: 25 maja 2006, 14:39

- Lokalizacja: koło.wlkp

Re: Plazma 4 osie na LinuxCNC

No fajnie.

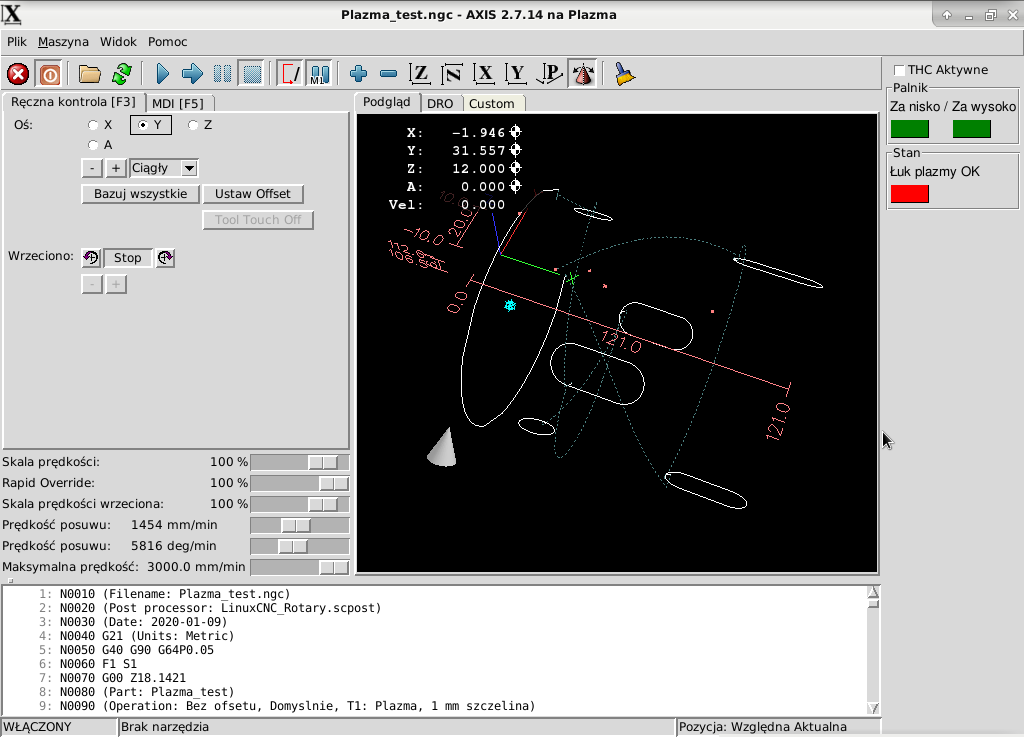

Tak na podsumowanie.

Kamara plazma ewaluowała

Kod: Zaznacz cały

N0010 (Filename: Plazma_test.ngc)

N0020 (Post processor: LinuxCNC_Rotary.scpost)

N0030 (Date: 2020-01-09)

N0040 G21 (Units: Metric)

N0050 G40 G90 G64P0.05

N0060 F1 S1

N0070 G00 Z18.1421

N0080 (Part: Plazma_test)

N0090 (Operation: Bez ofsetu, Domyslnie, T1: Plazma, 1 mm szczelina)

N0100 G00 X26.9200 Y-6.0800 Z14.0000 A0.0000

N0110 Z12.0000

N0120 Z12.0000

N0130 M03

N0140 G04 P1

N0150 G02 X25.0000 Y-8.0000 I-1.9200 J0.0000 F400.0

N0160 I0.0000 J8.0000

N0170 M05

N0180 G00 Z14.0000

N0190 X38.9200 Y-1.9200 Z18.1421 A90.0000

N0200 Z12.0000

N0210 Z12.0000

N0220 M03

N0230 G04 P1

N0240 G02 X37.0000 Y0.0000 I0.0000 J1.9200

N0250 X45.0000 Y8.0000 I8.0000 J0.0000

N0260 G01 X65.0000

N0270 G02 Y-8.0000 I0.0000 J-8.0000

N0280 G01 X45.0000

N0290 G02 X37.0000 Y0.0000 I0.0000 J8.0000

N0300 M05

N0310 G00 Z14.0000

N0320 X46.9200 Y-6.0800 Z18.1421 A-90.0000

N0330 Z12.0000

N0340 Z12.0000

N0350 M03

N0360 G04 P1

N0370 G02 X45.0000 Y-8.0000 I-1.9200 J0.0000

N0380 Y8.0000 I0.0000 J8.0000

N0390 G01 X65.0000

N0400 G02 Y-8.0000 I0.0000 J-8.0000

N0410 G01 X45.0000

N0420 M05

N0430 G00 Z14.0000

N0440 X26.9200 Y-6.0800 Z18.1421 A-180.0000

N0450 Z12.0000

N0460 Z12.0000

N0470 M03

N0480 G04 P1

N0490 G02 X25.0000 Y-8.0000 I-1.9200 J0.0000

N0500 I0.0000 J8.0000

N0510 M05

N0520 G00 Z14.0000

N0530 X5.0000 Y10.0000

N0540 Z12.0000

N0550 Z16.1421

N0560 M03

N0570 G04 P1

N0580 G01 Y-9.6226

N0590 Y9.8742 A-90.0000 F73209.6478

N0600 Y-9.7484 F400.0

N0610 Y9.7484 A0.0000 F73209.6478

N0620 Y-9.8742 F400.0

N0630 Y9.6226 A90.0000 F73209.6478

N0640 Y-8.4906 F400.0

N0650 M05

N0660 G00 Y-10.0000 Z14.0000

N0670 X86.9200 Y-1.9200 Z18.1421 A0.0000

N0680 Z12.0000

N0690 Z12.0000

N0700 M03

N0710 G04 P1

N0720 G02 X85.0000 Y0.0000 I0.0000 J1.9200

N0730 X93.0000 Y8.0000 I8.0000 J0.0000

N0740 G01 X113.0000

N0750 G02 Y-8.0000 I0.0000 J-8.0000

N0760 G01 X93.0000

N0770 G02 X85.0000 Y0.0000 I0.0000 J8.0000

N0780 M05

N0790 G00 Z14.0000

N0800 X86.9200 Y-1.9200 Z18.1421 A180.0000

N0810 Z12.0000

N0820 Z12.0000

N0830 M03

N0840 G04 P1

N0850 G02 X85.0000 Y0.0000 I0.0000 J1.9200

N0860 X93.0000 Y8.0000 I8.0000 J0.0000

N0870 G01 X113.0000

N0880 G02 Y-8.0000 I0.0000 J-8.0000

N0890 G01 X93.0000

N0900 G02 X85.0000 Y0.0000 I0.0000 J8.0000

N0910 (Operation: )

N0920 M05

N0930 G00 Z14.0000

N0940 X0.0000 Y-10.0000 Z18.1421 A90.0000

N0950 Z13.0000

N0960 Z18.1421

N0970 M05 M2-

senio

Autor tematu - ELITA FORUM (min. 1000)

- Posty w temacie: 42

- Posty: 1459

- Rejestracja: 25 maja 2006, 14:39

- Lokalizacja: koło.wlkp

Re: Plazma 4 osie na LinuxCNC

W Halu który wkleiłeś są dwie sekcje THC

Kod: Zaznacz cały

#***********************************************************

loadrt thcud

addf thcud servo-thread

#***********************************************************

#************************************************

net probe-in <= parport.0.pin-11-in

net TorchUp thcud.torch-up <= parport.0.pin-12-in

net TorchDown thcud.torch-down <= parport.0.pin-13-in

net ArcOK motion.digital-in-00 thcud.arc-ok <= parport.0.pin-15-in

net CurVel thcud.current-vel <= motion.current-vel

setp thcud.requested-vel 5

setp thcud.velocity-tol 2

setp thcud.correction-vel 0.002 # bylo 0.005

#************************************************-

kamar

- Lider FORUM (min. 2000)

- Posty w temacie: 39

- Posty: 16251

- Rejestracja: 18 wrz 2010, 06:17

- Lokalizacja: Kozienice

- Kontakt:

Re: Plazma 4 osie na LinuxCNC

Też nie wiem co tam jest.

Namieszałeś i tak nie wąsko, drugi dzień kombinuje z PP do Fusiona na plazmę, żaden z dostępnych nie generuje zetki.

Namieszałeś i tak nie wąsko, drugi dzień kombinuje z PP do Fusiona na plazmę, żaden z dostępnych nie generuje zetki.

-

senio

Autor tematu - ELITA FORUM (min. 1000)

- Posty w temacie: 42

- Posty: 1459

- Rejestracja: 25 maja 2006, 14:39

- Lokalizacja: koło.wlkp

Re: Plazma 4 osie na LinuxCNC

Ja miałem z tym farta. Ale tydzień przesiedziałem nad tym żeby te klocki poskładać, więc limitu czasu nie wyczerpałeś jeszcze

-

kamar

- Lider FORUM (min. 2000)

- Posty w temacie: 39

- Posty: 16251

- Rejestracja: 18 wrz 2010, 06:17

- Lokalizacja: Kozienice

- Kontakt:

Re: Plazma 4 osie na LinuxCNC

Tylko , że Tobie potrzebny a mnie to tak sobie

Pięć osiek to normalka, nawet na drutówkach

Pięć osiek to normalka, nawet na drutówkach

-

senio

Autor tematu - ELITA FORUM (min. 1000)

- Posty w temacie: 42

- Posty: 1459

- Rejestracja: 25 maja 2006, 14:39

- Lokalizacja: koło.wlkp

Re: Plazma 4 osie na LinuxCNC

Taki znalazłem

Kod: Zaznacz cały

/**

Copyright (C) 2012-2015 by Autodesk, Inc.

All rights reserved.

LinuxCNC (EMC2) post processor configuration for plasma.

$Revision: 41601 2e6200651f01fad70bd72491303b9729cd57fc6e $

$Date: 2018-03-01 05:36:56 $

FORKID {N/A}

*/

description = "LinuxCNC (EMC2) Plasma";

vendor = "LinuxCNC";

vendorUrl = "http://www.linuxcnc.org";

legal = "Copyright (C) 2012-2018 by Autodesk, Inc.";

certificationLevel = 2;

minimumRevision = 24000;

longDescription = "Generic post for LinuxCNC (EMC2) plasma cutters.";

extension = "ngc";

setCodePage("ascii");

capabilities = CAPABILITY_JET;

tolerance = spatial(0.002, MM);

minimumChordLength = spatial(0.01, MM);

minimumCircularRadius = spatial(0.01, MM);

maximumCircularRadius = spatial(1000, MM);

minimumCircularSweep = toRad(0.01);

maximumCircularSweep = toRad(180);

allowHelicalMoves = false; // for milling

allowedCircularPlanes = undefined; // allow any circular motion

// user-defined properties

properties = {

writeMachine: true, // write machine.

showSequenceNumbers: true, // show sequence numbers.

sequenceNumberStart: 10, // first sequence number.

sequenceNumberIncrement: 1, // increment for sequence numbers.

separateWordsWithSpace: true, // specifies that the words should be separated with a white space.

useRadius: false, // specifies that arcs should be output using the radius (R word) instead of the I, J, and K words.

dwellInSeconds: true, // specifies the dwell unit - use true:seconds and false:milliseconds.

useZ: true, // disable to output only XY motion.

useWorkOffsets: true, // enable to output G54, ... work offsets.

useCoolant: false, // enable to output coolant M-codes. E.g. M9.

useTool: false, // enable to output tool calls. E.g. T1.

useM30: true // enable to output M30 for program end.

};

// user-defined property definitions

propertyDefinitions = {

writeMachine: {title:"Write machine", description:"Output the machine settings in the header of the code.", group:0, type:"boolean"},

showSequenceNumbers: {title:"Use sequence numbers", description:"Use sequence numbers for each block of outputted code.", group:1, type:"boolean"},

sequenceNumberStart: {title:"Start sequence number", description:"The number at which to start the sequence numbers.", group:1, type:"integer"},

sequenceNumberIncrement: {title:"Sequence number increment", description:"The amount by which the sequence number is incremented by in each block.", group:1, type:"integer"},

separateWordsWithSpace: {title:"Separate words with space", description:"Adds spaces between words if 'yes' is selected.", type:"boolean"},

useRadius: {title:"Radius arcs", description:"If yes is selected, arcs are outputted using radius values rather than IJK.", type:"boolean"},

dwellInSeconds: {title:"Dwell in seconds", description:"Specifies the unit for dwelling, set to 'Yes' for seconds and 'No' for milliseconds.", type:"boolean"},

useZ: {title:"Use Z Values", description:"If disabled, all Z values are ommited.", type:"boolean"},

useWorkOffsets: {title:"Use work offsets", description:"Enable to allow the use of work offsets.", type:"boolean"},

useCoolant: {title:"Use coolant", description:"Enable to ouput coolant commands.", type:"boolean"},

useTool: {title:"Use tool", description:"Enable to ouptut tool calls. E.g. T1.", type:"boolean"},

useM30: {title:"Use M30", description:"Enable to output M30 for program end.", type:"boolean"}

};

var mapCoolantTable = new Table(

[9, 8, 7],

{initial:COOLANT_OFF, force:true},

"Invalid coolant mode"

);

var gFormat = createFormat({prefix:"G", decimals:1});

var mFormat = createFormat({prefix:"M", decimals:0});

var hFormat = createFormat({prefix:"H", decimals:0});

var dFormat = createFormat({prefix:"D", decimals:0});

var xyzFormat = createFormat({decimals:(unit == MM ? 3 : 4), forceDecimal:true, force:false});

var rFormat = xyzFormat; // radius

var feedFormat = createFormat({decimals:(unit == MM ? 1 : 2), forceDecimal:true});

var toolFormat = createFormat({decimals:0});

var rpmFormat = createFormat({decimals:0});

var secFormat = createFormat({decimals:3, forceDecimal:true}); // seconds - range 0.001-99999.999

var milliFormat = createFormat({decimals:0}); // milliseconds // range 1-9999

var xOutput = createVariable({prefix:"X", force:false}, xyzFormat);

var yOutput = createVariable({prefix:"Y", force:false}, xyzFormat);

var zOutput = createVariable({prefix:"Z", force:false}, xyzFormat);

var feedOutput = createVariable({prefix:"F"}, feedFormat);

var sOutput = createVariable({prefix:"S", force:true}, rpmFormat);

// circular output

var iOutput = createReferenceVariable({prefix:"I", force:true}, xyzFormat);

var jOutput = createReferenceVariable({prefix:"J", force:true}, xyzFormat);

var kOutput = createReferenceVariable({prefix:"K", force:true}, xyzFormat);

var gMotionModal = createModal({force:false}, gFormat); // modal group 1 // G0-G3

var gPlaneModal = createModal({onchange:function () {gMotionModal.reset();}}, gFormat); // modal group 2 // G17-19

var gAbsIncModal = createModal({}, gFormat); // modal group 3 // G90-91

var gUnitModal = createModal({}, gFormat); // modal group 6 // G20-21 or G70-71

var gCycleModal = createModal({}, gFormat); // modal group 9 // G81, ...

var gRetractModal = createModal({}, gFormat); // modal group 10 // G98-99

var WARNING_WORK_OFFSET = 0;

// collected state

var sequenceNumber;

var currentWorkOffset;

/**

Writes the specified block.

*/

function writeBlock() {

if (properties.showSequenceNumbers) {

writeWords2("N" + (sequenceNumber % 100000), arguments);

sequenceNumber += properties.sequenceNumberIncrement;

} else {

writeWords(arguments);

}

}

/**

Writes the specified optional block.

*/

function writeOptionalBlock() {

if (properties.showSequenceNumbers) {

var words = formatWords(arguments);

if (words) {

writeWords("/", "N" + (sequenceNumber % 10000), words);

sequenceNumber += properties.sequenceNumberIncrement;

if (sequenceNumber >= 10000) {

sequenceNumber = properties.sequenceNumberStart;

}

}

} else {

writeWords2("/", arguments);

}

}

function formatComment(text) {

return "(" + String(text).replace(/[\(\)]/g, "") + ")";

}

/**

Output a comment.

*/

function writeComment(text) {

writeln(formatComment(text));

}

function onOpen() {

if (properties.useRadius) {

maximumCircularSweep = toRad(90); // avoid potential center calculation errors for CNC

}

if (!properties.useZ) {

zOutput.disable();

}

if (!properties.separateWordsWithSpace) {

setWordSeparator("");

}

sequenceNumber = properties.sequenceNumberStart;

writeln("%");

writeln("S1000");

if (programComment) {

writeComment(programComment);

}

// dump machine configuration

var vendor = machineConfiguration.getVendor();

var model = machineConfiguration.getModel();

var description = machineConfiguration.getDescription();

if (properties.writeMachine && (vendor || model || description)) {

writeComment(localize("Machine"));

if (vendor) {

writeComment(" " + localize("vendor") + ": " + vendor);

}

if (model) {

writeComment(" " + localize("model") + ": " + model);

}

if (description) {

writeComment(" " + localize("description") + ": " + description);

}

}

switch (unit) {

case IN:

writeBlock(gUnitModal.format(20)); // or use M20

break;

case MM:

writeBlock(gUnitModal.format(21)); // or use M21

break;

}

if ((getNumberOfSections() > 0) && (getSection(0).workOffset == 0)) {

for (var i = 0; i < getNumberOfSections(); ++i) {

if (getSection(i).workOffset > 0) {

error(localize("Using multiple work offsets is not possible if the initial work offset is 0."));

return;

}

}

}

// absolute coordinates

if (properties.useZ) {

writeBlock(gAbsIncModal.format(90), conditional(properties.useZ, gPlaneModal.format(17)));

} else {

writeBlock(gAbsIncModal.format(90));

}

}

function onComment(message) {

writeComment(message);

}

/** Force output of X, Y, and Z. */

function forceXYZ() {

xOutput.reset();

yOutput.reset();

}

/** Force output of X, Y, Z, and F on next output. */

function forceAny() {

forceXYZ();

feedOutput.reset();

}

function onSection() {

var insertToolCall = isFirstSection() ||

currentSection.getForceToolChange && currentSection.getForceToolChange() ||

(tool.number != getPreviousSection().getTool().number);

var retracted = false; // specifies that the tool has been retracted to the safe plane

var newWorkOffset = isFirstSection() ||

(getPreviousSection().workOffset != currentSection.workOffset); // work offset changes

var newWorkPlane = isFirstSection() ||

!isSameDirection(getPreviousSection().getGlobalFinalToolAxis(), currentSection.getGlobalInitialToolAxis());

if (insertToolCall || newWorkOffset || newWorkPlane) {

// stop spindle before retract during tool change

if (insertToolCall && !isFirstSection()) {

onCommand(COMMAND_STOP_SPINDLE);

}

// retract to safe plane

if (properties.useZ) {

retracted = true;

writeBlock(gFormat.format(28), gAbsIncModal.format(91), "Z" + xyzFormat.format(0)); // retract

writeBlock(gAbsIncModal.format(90));

zOutput.reset();

}

}

writeln("");

if (hasParameter("operation-comment")) {

var comment = getParameter("operation-comment");

if (comment) {

writeComment(comment);

}

}

if (properties.useTool) {

if (currentSection.type == TYPE_JET) {

switch (tool.type) {

case TOOL_PLASMA_CUTTER:

break;

/*

case TOOL_MARKER:

break;

*/

default:

error(localize("The CNC does not support the required tool/process. Only plasma cutting is supported."));

return;

}

switch (currentSection.jetMode) {

case JET_MODE_THROUGH:

break;

case JET_MODE_ETCHING:

break;

case JET_MODE_VAPORIZE:

error(localize("Vaporize cutting mode is not supported."));

break;

default:

error(localize("Unsupported cutting mode."));

return;

}

var toolNumber = 1; // plasma

if (currentSection.jetMode == JET_MODE_ETCHING) {

toolNumber = 2; // marker

}

writeBlock(mFormat.format(6), "T" + toolFormat.format(toolNumber));

} else {

writeBlock(mFormat.format(6), "T" + toolFormat.format(tool.number));

}

}

if (tool.comment) {

writeComment(tool.comment);

}

if ((currentSection.type == TYPE_MILLING) &&

(insertToolCall ||

isFirstSection() ||

(rpmFormat.areDifferent(tool.spindleRPM, sOutput.getCurrent())) ||

(tool.clockwise != getPreviousSection().getTool().clockwise))) {

if (tool.spindleRPM < 1) {

error(localize("Spindle speed out of range."));

}

if (tool.spindleRPM > 99999) {

warning(localize("Spindle speed exceeds maximum value."));

}

writeBlock(

sOutput.format(tool.spindleRPM), mFormat.format(tool.clockwise ? 3 : 4)

);

}

// wcs

if (properties.useWorkOffsets) {

if (insertToolCall) { // force work offset when changing tool

currentWorkOffset = undefined;

}

var workOffset = currentSection.workOffset;

if (workOffset == 0) {

warningOnce(localize("Work offset has not been specified. Using G54 as WCS."), WARNING_WORK_OFFSET);

workOffset = 1;

}

if (workOffset > 0) {

if (workOffset > 6) {

var p = workOffset - 6; // 1->...

if (p > 100) {

error(localize("Work offset out of range."));

} else {

if (workOffset != currentWorkOffset) {

writeBlock(gFormat.format(54.1), "P" + p); // G54.1P

currentWorkOffset = workOffset;

}

}

} else {

if (workOffset != currentWorkOffset) {

writeBlock(gFormat.format(53 + workOffset)); // G54->G59

currentWorkOffset = workOffset;

}

}

}

}

{ // pure 3D

var remaining = currentSection.workPlane;

if (!isSameDirection(remaining.forward, new Vector(0, 0, 1))) {

error(localize("Tool orientation is not supported."));

return;

}

setRotation(remaining);

}

// set coolant after we have positioned at Z

if (properties.useCoolant) {

var c = mapCoolantTable.lookup(tool.coolant);

if (c) {

writeBlock(mFormat.format(c));

} else {

warning(localize("Coolant not supported."));

}

}

forceAny();

var initialPosition = getFramePosition(currentSection.getInitialPosition());

if (!retracted && properties.useZ) {

if (getCurrentPosition().z < initialPosition.z) {

writeBlock(gMotionModal.format(0), zOutput.format(initialPosition.z));

}

}

gMotionModal.reset();

if (true) {

gMotionModal.reset();

writeBlock(conditional(properties.useZ, gPlaneModal.format(17)));

if (properties.useZ) {

writeBlock(

gAbsIncModal.format(90),

gMotionModal.format(0), gFormat.format(43),

xOutput.format(initialPosition.x), yOutput.format(initialPosition.y), zOutput.format(initialPosition.z),

hFormat.format(tool.lengthOffset)

);

} else {

writeBlock(

gAbsIncModal.format(90),

gMotionModal.format(0),

xOutput.format(initialPosition.x), yOutput.format(initialPosition.y)

);

}

} else {

writeBlock(

gAbsIncModal.format(90),

gMotionModal.format(0),

xOutput.format(initialPosition.x),

yOutput.format(initialPosition.y),

zOutput.format(initialPosition.z)

);

}

writeBlock(

gAbsIncModal.format(90),

gMotionModal.format(0),

xOutput.format(initialPosition.x), yOutput.format(initialPosition.y), zOutput.format(initialPosition.z)

);

// could use G31 Zz Ii Ss Cc Ff for seek sensing

}

function onDwell(seconds) {

if (seconds > 99999.999) {

warning(localize("Dwelling time is out of range."));

}

if (properties.dwellInSeconds) {

writeBlock(gFormat.format(4), "X" + secFormat.format(seconds));

} else {

// P unit is setting in control!

var milliseconds = clamp(1, seconds * 1000, 99999999);

writeBlock(gFormat.format(4), "P" + milliFormat.format(milliseconds));

}

}

function onSpindleSpeed(spindleSpeed) {

writeBlock(sOutput.format(spindleSpeed));

}

function onCycle() {

writeBlock(conditional(properties.useZ, gPlaneModal.format(17)));

}

function getCommonCycle(x, y, z, r) {

forceXYZ();

return [xOutput.format(x), yOutput.format(y),

zOutput.format(z),

"R" + xyzFormat.format(r)];

}

function onCyclePoint(x, y, z) {

if (!properties.useZ) {

error(localize("Z must be enabled by setting the 'useZ' property to use drilling cycles."));

return;

}

if (isFirstCyclePoint()) {

repositionToCycleClearance(cycle, x, y, z);

// return to initial Z which is clearance plane and set absolute mode

var F = cycle.feedrate;

var P = (cycle.dwell == 0) ? 0 : clamp(1, cycle.dwell * 1000, 99999); // in milliseconds

switch (cycleType) {

case "drilling":

writeBlock(

gRetractModal.format(98), gAbsIncModal.format(90), gCycleModal.format(81),

getCommonCycle(x, y, z, cycle.retract),

feedOutput.format(F)

);

break;

case "counter-boring":

if (P > 0) {

writeBlock(

gRetractModal.format(98), gAbsIncModal.format(90), gCycleModal.format(82),

getCommonCycle(x, y, z, cycle.retract),

"P" + milliFormat.format(P),

feedOutput.format(F)

);

} else {

writeBlock(

gRetractModal.format(98), gAbsIncModal.format(90), gCycleModal.format(81),

getCommonCycle(x, y, z, cycle.retract),

feedOutput.format(F)

);

}

break;

case "chip-breaking":

expandCyclePoint(x, y, z);

break;

case "deep-drilling":

if (P > 0) {

expandCyclePoint(x, y, z);

} else {

writeBlock(

gRetractModal.format(98), gAbsIncModal.format(90), gCycleModal.format(83),

getCommonCycle(x, y, z, cycle.retract),

"Q" + xyzFormat.format(cycle.incrementalDepth),

feedOutput.format(F)

);

}

break;

case "fine-boring": // not supported

expandCyclePoint(x, y, z);

break;

case "reaming":

writeBlock(

gRetractModal.format(98), gAbsIncModal.format(90), gCycleModal.format(85),

getCommonCycle(x, y, z, cycle.retract),

feedOutput.format(F)

);

break;

case "boring":

if (P > 0) {

expandCyclePoint(x, y, z);

} else {

writeBlock(

gRetractModal.format(98), gAbsIncModal.format(90), gCycleModal.format(85),

getCommonCycle(x, y, z, cycle.retract),

feedOutput.format(F)

);

}

break;

default:

expandCyclePoint(x, y, z);

}

} else {

if (cycleExpanded) {

expandCyclePoint(x, y, z);

} else {

var _x = xOutput.format(x);

var _y = yOutput.format(y);

if (!_x && !_y) {

xOutput.reset(); // at least one axis is required

_x = xOutput.format(x);

}

writeBlock(_x, _y);

}

}

}

function onCycleEnd() {

if (!cycleExpanded) {

writeBlock(gCycleModal.format(80));

zOutput.reset();

}

}

var pendingRadiusCompensation = -1;

function onRadiusCompensation() {

pendingRadiusCompensation = radiusCompensation;

}

var shapeArea = 0;

var shapePerimeter = 0;

var shapeSide = "inner";

var cuttingSequence = "";

function onParameter(name, value) {

if ((name == "action") && (value == "pierce")) {

// add delay if desired

} else if (name == "shapeArea") {

shapeArea = value;

} else if (name == "shapePerimeter") {

shapePerimeter = value;

} else if (name == "shapeSide") {

shapeSide = value;

} else if (name == "beginSequence") {

if (value == "piercing") {

if (cuttingSequence != "piercing") {

if (properties.allowHeadSwitches) {

// Allow head to be switched here

// writeBlock(mFormat.format(0), '"Switch head for piercing."');

}

}

} else if (value == "cutting") {

if (cuttingSequence == "piercing") {

if (properties.allowHeadSwitches) {

// Allow head to be switched here

// writeBlock(mFormat.format(0), '"Switch head for cutting."');

}

}

}

cuttingSequence = value;

}

}

function onPower(power) {

writeBlock(mFormat.format(power ? 3 : 5)); // plasma on/off

writeBlock(gFormat.format(04), "P 0.5"); // pause for plasma to start

}

function onRapid(_x, _y, _z) {

// manual states linear interpolation - so not dog-leg motion expected

// at least one axis is required

if (pendingRadiusCompensation >= 0) {

// ensure that we end at desired position when compensation is turned off

xOutput.reset();

yOutput.reset();

}

var x = xOutput.format(_x);

var y = yOutput.format(_y);

var z = zOutput.format(_z);

if (x || y || z) {

if (pendingRadiusCompensation >= 0) {

pendingRadiusCompensation = -1;

var toolNumber = tool.number;

if (currentSection.type == TYPE_JET) {

toolNumber = 1; // plasma

if (currentSection.jetMode == JET_MODE_ETCHING) {

toolNumber = 2; // marker

}

}

switch (radiusCompensation) {

case RADIUS_COMPENSATION_LEFT:

writeBlock(gFormat.format(41), dFormat.format(toolNumber));

break;

case RADIUS_COMPENSATION_RIGHT:

writeBlock(gFormat.format(42), dFormat.format(toolNumber));

break;

default:

writeBlock(gFormat.format(40));

}

}

writeBlock(gMotionModal.format(0), x, y, z);

feedOutput.reset();

}

}

function onLinear(_x, _y, _z, feed) {

// at least one axis is required

if (pendingRadiusCompensation >= 0) {

// ensure that we end at desired position when compensation is turned off

xOutput.reset();

yOutput.reset();

}

var x = xOutput.format(_x);

var y = yOutput.format(_y);

var z = zOutput.format(_z);

var f = feedOutput.format(feed);

if (x || y || z) {

if (pendingRadiusCompensation >= 0) {

pendingRadiusCompensation = -1;

var toolNumber = tool.number;

if (currentSection.type == TYPE_JET) {

toolNumber = 1; // plasma

if (currentSection.jetMode == JET_MODE_ETCHING) {

toolNumber = 2; // marker

}

}

switch (radiusCompensation) {

case RADIUS_COMPENSATION_LEFT:

writeBlock(gFormat.format(41), dFormat.format(toolNumber));

break;

case RADIUS_COMPENSATION_RIGHT:

writeBlock(gFormat.format(42), dFormat.format(toolNumber));

break;

default:

}

}

writeBlock(gMotionModal.format(1), x, y, z, f);

} else if (f) {

if (getNextRecord().isMotion()) { // try not to output feed without motion

feedOutput.reset(); // force feed on next line

} else {

writeBlock(gMotionModal.format(1), f);

}

}

}

function onRapid5D(_x, _y, _z, _a, _b, _c) {

error(localize("The CNC does not support 5-axis simultaneous toolpath."));

}

function onLinear5D(_x, _y, _z, _a, _b, _c, feed) {

error(localize("The CNC does not support 5-axis simultaneous toolpath."));

}

function onCircular(clockwise, cx, cy, cz, x, y, z, feed) {

// one of X/Y and I/J are required and likewise

if (pendingRadiusCompensation >= 0) {

error(localize("Radius compensation cannot be activated/deactivated for a circular move."));

return;

}

var start = getCurrentPosition();

if (isFullCircle()) {

if (properties.useRadius || isHelical()) { // radius mode does not support full arcs

linearize(tolerance);

return;

}

switch (getCircularPlane()) {

case PLANE_XY:

writeBlock(conditional(properties.useZ, gPlaneModal.format(17)), gMotionModal.format(clockwise ? 2 : 3), xOutput.format(x), iOutput.format(cx - start.x, 0), jOutput.format(cy - start.y, 0), feedOutput.format(feed));

break;

case PLANE_ZX:

if (properties.useZ) {

writeBlock(conditional(properties.useZ, gPlaneModal.format(18)), gMotionModal.format(clockwise ? 2 : 3), zOutput.format(z), iOutput.format(cx - start.x, 0), kOutput.format(cz - start.z, 0), feedOutput.format(feed));

} else {

linearize(tolerance);

}

break;

case PLANE_YZ:

if (properties.useZ) {

writeBlock(conditional(properties.useZ, gPlaneModal.format(19)), gMotionModal.format(clockwise ? 2 : 3), yOutput.format(y), jOutput.format(cy - start.y, 0), kOutput.format(cz - start.z, 0), feedOutput.format(feed));

} else {

linearize(tolerance);

}

break;

default:

linearize(tolerance);

}

} else if (!properties.useRadius) {

switch (getCircularPlane()) {

case PLANE_XY:

writeBlock(conditional(properties.useZ, gPlaneModal.format(17)), gMotionModal.format(clockwise ? 2 : 3), xOutput.format(x), yOutput.format(y), zOutput.format(z), iOutput.format(cx - start.x, 0), jOutput.format(cy - start.y, 0), feedOutput.format(feed));

break;

case PLANE_ZX:

if (properties.useZ) {

writeBlock(conditional(properties.useZ, gPlaneModal.format(18)), gMotionModal.format(clockwise ? 2 : 3), xOutput.format(x), yOutput.format(y), zOutput.format(z), iOutput.format(cx - start.x, 0), kOutput.format(cz - start.z, 0), feedOutput.format(feed));

} else {

linearize(tolerance);

}

break;

case PLANE_YZ:

if (properties.useZ) {

writeBlock(conditional(properties.useZ, gPlaneModal.format(19)), gMotionModal.format(clockwise ? 2 : 3), xOutput.format(x), yOutput.format(y), zOutput.format(z), jOutput.format(cy - start.y, 0), kOutput.format(cz - start.z, 0), feedOutput.format(feed));

} else {

linearize(tolerance);

}

break;

default:

linearize(tolerance);

}

} else { // use radius mode

var r = getCircularRadius();

if (toDeg(getCircularSweep()) > 180) {

r = -r; // allow up to <360 deg arcs

}

switch (getCircularPlane()) {

case PLANE_XY:

writeBlock(conditional(properties.useZ, gPlaneModal.format(17)), gMotionModal.format(clockwise ? 2 : 3), xOutput.format(x), yOutput.format(y), "R" + rFormat.format(r), feedOutput.format(feed));

break;

case PLANE_ZX:

if (properties.useZ) {

writeBlock(conditional(properties.useZ, gPlaneModal.format(18)), gMotionModal.format(clockwise ? 2 : 3), xOutput.format(x), yOutput.format(y), zOutput.format(z), "R" + rFormat.format(r), feedOutput.format(feed));

} else {

linearize(tolerance);

}

break;

case PLANE_YZ:

if (properties.useZ) {

writeBlock(conditional(properties.useZ, gPlaneModal.format(19)), gMotionModal.format(clockwise ? 2 : 3), xOutput.format(x), yOutput.format(y), zOutput.format(z), "R" + rFormat.format(r), feedOutput.format(feed));

} else {

linearize(tolerance);

}

break;

default:

linearize(tolerance);

}

}

}

var mapCommand = {

COMMAND_STOP:0,

COMMAND_OPTIONAL_STOP:1,

COMMAND_SPINDLE_CLOCKWISE:3,

COMMAND_SPINDLE_COUNTERCLOCKWISE:4,

COMMAND_STOP_SPINDLE:5,

COMMAND_COOLANT_ON:8,

COMMAND_COOLANT_OFF:9

};

function onCommand(command) {

switch (command) {

case COMMAND_START_SPINDLE:

onCommand(tool.clockwise ? COMMAND_SPINDLE_CLOCKWISE : COMMAND_SPINDLE_COUNTERCLOCKWISE);

return;

case COMMAND_POWER_ON:

return;

case COMMAND_POWER_OFF:

return;

case COMMAND_LOCK_MULTI_AXIS:

return;

case COMMAND_UNLOCK_MULTI_AXIS:

return;

case COMMAND_BREAK_CONTROL:

return;

case COMMAND_TOOL_MEASURE:

return;

}

var stringId = getCommandStringId(command);

var mcode = mapCommand[stringId];

if (mcode != undefined) {

writeBlock(mFormat.format(mcode));

} else {

onUnsupportedCommand(command);

}

}

function onSectionEnd() {

writeBlock(conditional(properties.useZ, gPlaneModal.format(17)));

forceAny();

}

function onClose() {

if (properties.useZ || properties.useM30) {

writeln("");

}

if (properties.useZ) {

writeBlock(gFormat.format(28), gAbsIncModal.format(91), "Z" + xyzFormat.format(0)); // retract

writeBlock(gAbsIncModal.format(90));

zOutput.reset();

}

if (properties.useZ) {

writeBlock(gFormat.format(28)); // move to reference point #1 - tool change position by default

}

if (properties.useM30) {

writeBlock(mFormat.format(30));

}

writeln("%");

]