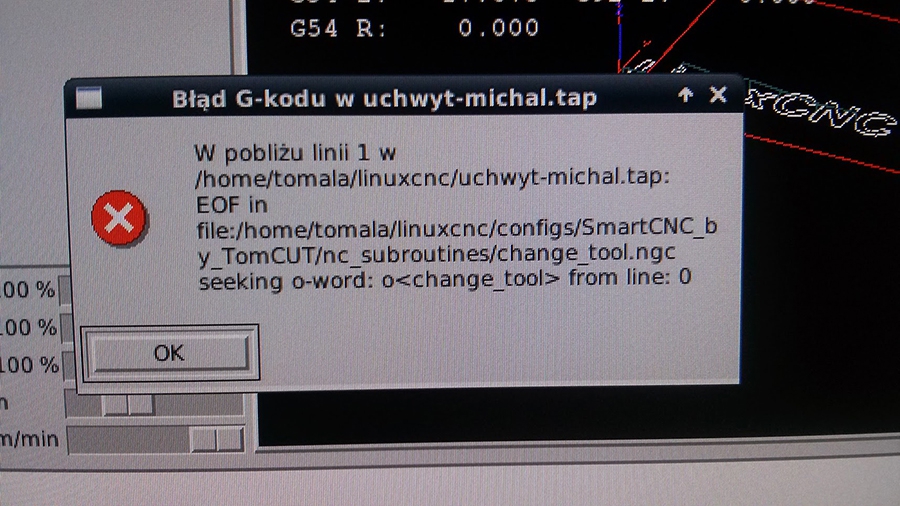

Nie mam pojęcia czym on jest spowodowany i nie potrafię sobie z nim poradzić. bardzo proszę o pomoc

Zmiany w INI

[EMC]

MACHINE = SmartCNC_by_TomCUT

DEBUG = 0

[DISPLAY]

DISPLAY = axis

EDITOR = gedit

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

ARCDIVISION = 64

GRIDS = 10mm 20mm 50mm 100mm 1in 2in 5in 10in

MAX_FEED_OVERRIDE = 1.2

MIN_SPINDLE_OVERRIDE = 0.5

MAX_SPINDLE_OVERRIDE = 1.2

DEFAULT_LINEAR_VELOCITY = 2.50

MIN_LINEAR_VELOCITY = 0

MAX_LINEAR_VELOCITY = 25.00

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/tomala/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

PYVCP = custompanel.xml

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[toolsensor]

X = 350

Y = 150

Z = 55

MAXPROBE=60

[after_change_position]

X = 50

Y = 19

Z = 1

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

TOOL_CHANGE_POSITION = 50 19 1

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

BASE_PERIOD = 50000

SERVO_PERIOD = 1000000

[HAL]

HALUI = halui

HALFILE = SmartCNC_by_TomCUT.hal

HALFILE = custom.hal

POSTGUI_HALFILE = custom_postgui.hal

[TRAJ]

AXES = 3

COORDINATES = X Y Z

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_VELOCITY = 2.50

MAX_VELOCITY = 25.00

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 23.75

MAX_ACCELERATION = 750.0

STEPGEN_MAXACCEL = 937.5

SCALE = 800.0

FERROR = 1

MIN_FERROR = .25

MIN_LIMIT = -0.001

MAX_LIMIT = 440.0

HOME_OFFSET = 0.0

[AXIS_1]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 23.75

MAX_ACCELERATION = 750.0

STEPGEN_MAXACCEL = 937.5

SCALE = 800.0

FERROR = 1

MIN_FERROR = .25

MIN_LIMIT = -0.001

MAX_LIMIT = 260.0

HOME_OFFSET = 0.0

[AXIS_2]

TYPE = LINEAR

HOME = 75.0

MAX_VELOCITY = 23.75

MAX_ACCELERATION = 500.0

STEPGEN_MAXACCEL = 625.0

SCALE = 800.0

FERROR = 1

MIN_FERROR = .25

MIN_LIMIT = 0.0

MAX_LIMIT = 75.001

HOME_OFFSET = 75.0

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

SUBROUTINE_PATH = ./nc_subroutines

REMAP=M6 modalgroup=6 ngc=change_tool

[HALUI]

MDI_COMMAND = o<tool_probe> call

tool_probe.ngc

o<tool_probe> sub

G73

G21

G90

G53 G0 Z0

G53 G0 X #<_ini[toolsensor]x> Y #<_ini[toolsensor]y>

G53 G0 Z #<_ini[toolsensor]z>

G91

G38.3 Z #<_ini[toolsensor]maxprobe> F200

G38.4 Z10 F1

G90

#1000=[#5223+#5063] (save reference tool length from Z 0 offset)

G53 G1 Z #<_ini[after_change_position]z> F1300

G53 G0 X #<_ini[after_change_position]x> Y #<_ini[after_change_position]y>

o<tool_probe> endsub

m2

change_tool.ngc

o<change_tool> sub

M6

G73

G21

G90

G53 G0 Z0

G53 G0 X #<_ini[toolsensor]x> Y #<_ini[toolsensor]y>

G53 G0 Z #<_ini[toolsensor]z>

G91

G38.3 Z #<_ini[toolsensor]maxprobe> F200

G38.4 Z10 F1

G90

G92 Z[#1000-#5223]

G53 G1 Z #<_ini[after_change_position]z> F1300

G53 G0 X #<_ini[after_change_position]x> Y #<_ini[after_change_position]y>

o<change_tool> endsub

M2