Znaleziono 3 wyniki

Wróć do „ponar remo fwe 16 wobbly table y axis”

- 16 sie 2023, 19:20

- Forum: Frezarka - konstrukcja metalowa

- Temat: ponar remo fwe 16 wobbly table y axis

- Odpowiedzi: 7

- Odsłony: 1652

Re: ponar remo fwe 16 wobbly table y axis

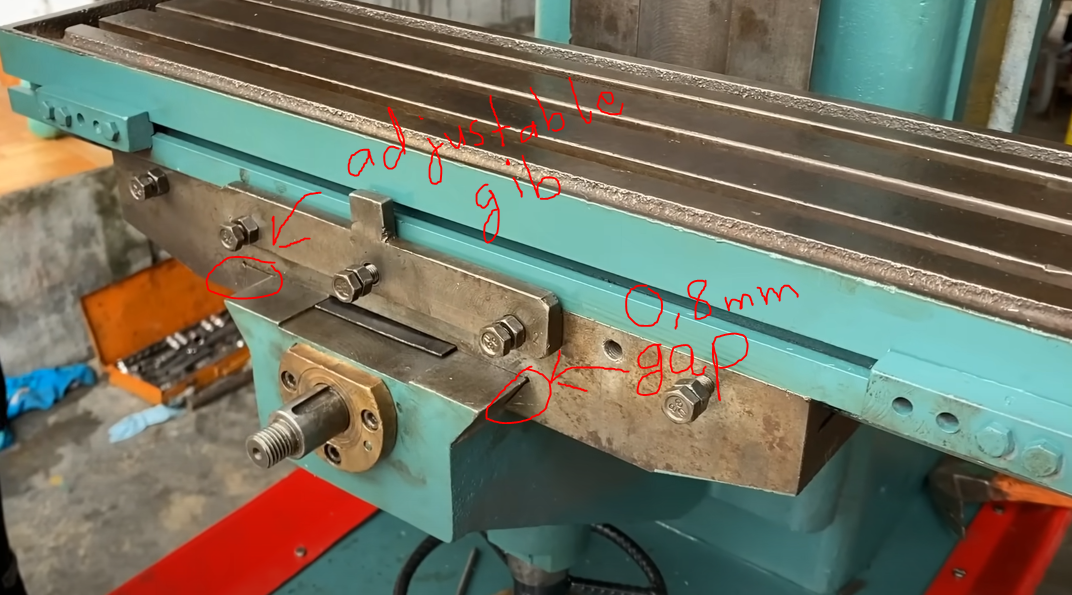

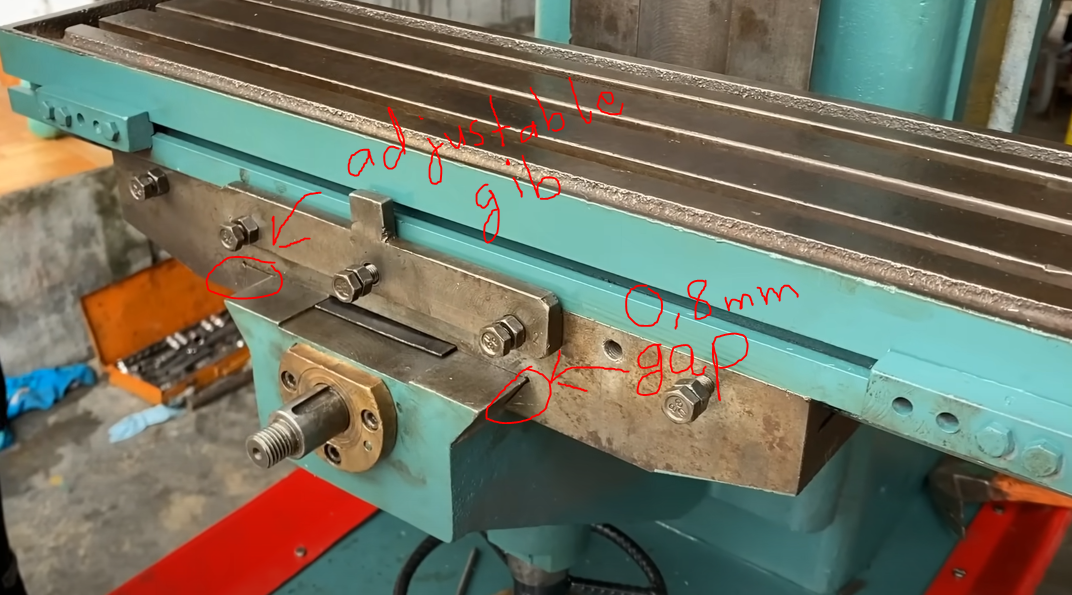

Btw if someone has the same maching as i do would you be able to send me the measurements of the gib from y axis i included a picture for better understanding.

- 15 sie 2023, 23:26

- Forum: Frezarka - konstrukcja metalowa

- Temat: ponar remo fwe 16 wobbly table y axis

- Odpowiedzi: 7

- Odsłony: 1652

Re: ponar remo fwe 16 wobbly table y axis

First of all thank you for the response the reason you state which could cause the table wiggle seems reasonable but after talking to the selller and also looking at the contact surfaces i highly doubt it was working hard or often in use. All the contact surfaces on the x, y, z axis still have factory scraping on them and i even checked the surfaces for even contact with blue dye. Could it be that the leadscrew is not perfectly in the middle or that the gib which is installed in the y axis was made once while a repair and it has the wrong dimension (to small)?

- 15 sie 2023, 20:19

- Forum: Frezarka - konstrukcja metalowa

- Temat: ponar remo fwe 16 wobbly table y axis

- Odpowiedzi: 7

- Odsłony: 1652

ponar remo fwe 16 wobbly table y axis

Hey there,

i was wondering if you guys could help me with the table wooble i have. The x and z axis are smooth and solid without any play but the y axis has a gap of arround 0,8,mm on the solid dovetail ( not the side where the adjustable gib is). I tried tightening the adjustment screws of the gib but the wiggle only stops if i really turn them tight and then i am not able to move the table in y axis anymore. The Leadscrew and the nut are prefectly fine with minimal backlash. I disassembled the machine and cleaned the table. I also checked all the gibs for even contact with blue die. All the surfaces are still scraped without any real wear marks. For now i added a brass stripe with the thickness of 0,8mm into the gap and the table stopped to wobble completly but i am still curious if there s not another way to get that gap / play out of the machine table. Remachining would be an option but honestly for the things i am making and what the machine cost me that would be to much.

Here is a picture for better understanding

here is a picture of it before i cleaned it:

i was wondering if you guys could help me with the table wooble i have. The x and z axis are smooth and solid without any play but the y axis has a gap of arround 0,8,mm on the solid dovetail ( not the side where the adjustable gib is). I tried tightening the adjustment screws of the gib but the wiggle only stops if i really turn them tight and then i am not able to move the table in y axis anymore. The Leadscrew and the nut are prefectly fine with minimal backlash. I disassembled the machine and cleaned the table. I also checked all the gibs for even contact with blue die. All the surfaces are still scraped without any real wear marks. For now i added a brass stripe with the thickness of 0,8mm into the gap and the table stopped to wobble completly but i am still curious if there s not another way to get that gap / play out of the machine table. Remachining would be an option but honestly for the things i am making and what the machine cost me that would be to much.

Here is a picture for better understanding

here is a picture of it before i cleaned it: